How Automation Is Changing the Manufacturing Industry

Automation is fundamentally transforming the manufacturing industry. Advanced robotics and artificial intelligence are streamlining operations, enhancing efficiency and precision. This shift not only minimizes downtime but also optimizes resource allocation. However, the integration of these technologies raises significant questions about workforce dynamics and the need for continuous retraining. As the industry progresses toward smart factories, the balance between automation and human involvement will be critical in shaping its future. What challenges and opportunities lie ahead?

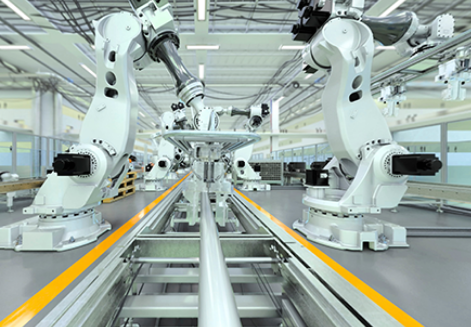

The Role of Robotics in Manufacturing

Robotics has revolutionized the manufacturing landscape by enhancing efficiency and precision in production processes.

Through advanced robotic integration, manufacturers can streamline operations, yet they face significant automation challenges, such as workforce adaptation and initial implementation costs.

Addressing these hurdles is essential for companies to fully leverage robotics, ensuring that technological advancements translate into sustainable productivity and autonomy, ultimately fostering a more liberated manufacturing environment.

Enhancing Efficiency With Artificial Intelligence

Artificial intelligence (AI) is becoming a cornerstone in the quest for enhanced efficiency within manufacturing operations.

By implementing predictive maintenance strategies, manufacturers can anticipate equipment failures, reducing downtime and optimizing productivity.

Furthermore, the integration of AI within smart factories enables real-time data analysis, facilitating informed decision-making and streamlined processes.

This technological evolution fosters a manufacturing environment that prioritizes operational excellence and resource optimization.

Impact on Workforce Dynamics

The integration of automation technologies is reshaping workforce dynamics in the manufacturing sector, creating a paradigm shift in job roles and skill requirements.

While job displacement is a concern, it also necessitates skill adaptation among workers to thrive in a more technologically advanced environment.

This evolution demands a recalibration of workforce training programs to foster a culture of continuous learning and adaptability.

Future Trends in Manufacturing Automation

As manufacturers increasingly embrace advanced automation technologies, the future landscape of the industry is poised for significant transformation.

The rise of smart factories will enable real-time data integration, enhancing operational efficiency.

Concurrently, predictive maintenance will minimize downtime by anticipating equipment failures.

These trends promise to optimize production processes, ultimately offering manufacturers greater flexibility and responsiveness in a competitive global market.

Conclusion

As the manufacturing industry adapts to the increasing prevalence of automation, it mirrors the transformation of a once-rigid river into a dynamic, flowing stream. Just as a river carves new pathways while nourishing its surroundings, automation reshapes manufacturing processes while fostering innovation and efficiency. However, like the ecosystem that relies on both water and land, a balanced integration of technology and human skill is essential to sustain growth and resilience in this evolving landscape.